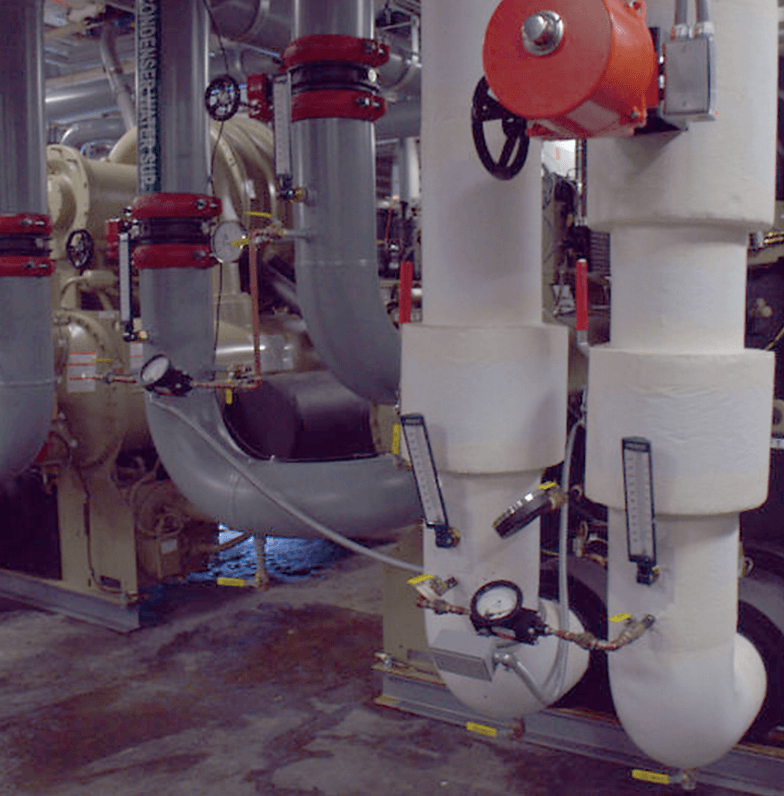

McKenney’s provided a turnkey design/build solution to replace an outdated chiller plant in the operating classroom complex of a government training center.

THE CHALLENGE

The specified chillers were much larger than the training center’s existing units, would not fit in the existing central plant’s configuration, and jeopardized the project’s timing and budget. Since training was in session, chilled water service could not be interrupted, and temporary chillers were beyond the budget scope.

THE SOLUTION

McKenney’s implemented the turnkey design solution in phases and used existing central plant equipment during new central plant construction to minimize shutdowns and stay within budget. A redesign of the central plant was necessary to accommodate the new equipment, and installation took place during four complicated, prolonged shutdowns on weekends.

THE RESULTS

Although the scope of work dramatically changed, McKenney’s executed and completed this complicated turnkey energy project on time and within budget without interrupting chilled water service. The energy savings now achieved will pay for the project costs.